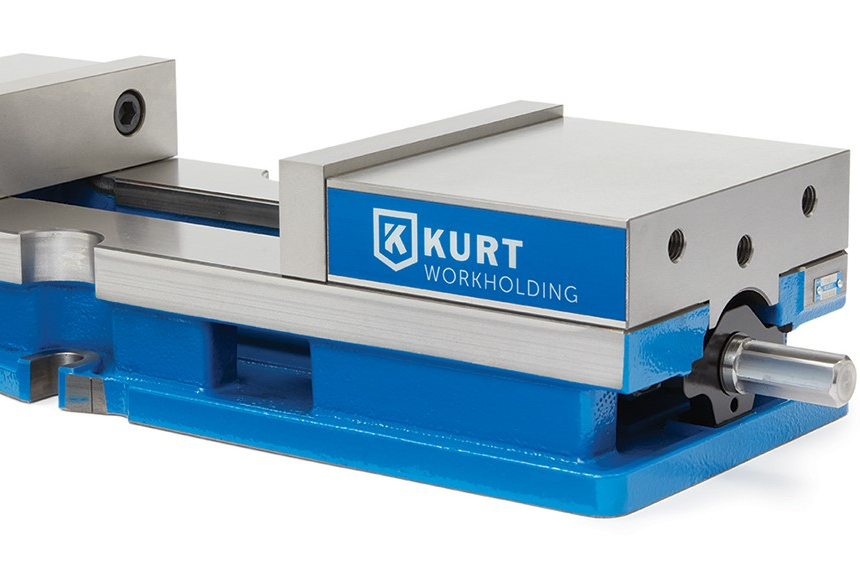

Kurt Vises, manufactured by Kurt Manufacturing, have set the standard for precision workholding in industries requiring high levels of accuracy and reliability. As a leader in the manufacturing of vises for critical sectors such as aerospace, automotive, defense, oil, and semiconductor industries, Kurt Vises have earned their place as indispensable tools in precision machining and manufacturing. In this comprehensive guide, we will explore the history, types, applications, advantages, and maintenance of Kurt Vises, ensuring you have the complete knowledge to make informed decisions about these essential tools.

The Legacy of Kurt Manufacturing

Founded in 1946, Kurt Manufacturing has built a strong reputation for its commitment to quality and continuous innovation. Originating in Minneapolis, the company rapidly expanded its capabilities and became known for producing high-precision workholding tools, notably the Kurt Vise. The Kurt Vise revolutionized workholding technology in the 1950s and became a cornerstone in industries where precision is paramount. Over the years, Kurt Manufacturing has remained at the forefront of technological advancements, offering a range of vise models to suit the diverse needs of the manufacturing world.

Types of Kurt Vises and Their Industrial Applications

Kurt Vises are engineered to meet the specific demands of different industries. Each type is designed with precision and durability in mind, ensuring machinists can rely on them for the most challenging tasks.

1. High-Density Vises: Compact Powerhouses for High-Speed Machining

High-density vises are built for environments where space optimization is critical. They are particularly useful in high-speed machining settings, such as those found in the semiconductor and electronics industries. These vises are compact yet capable of securing workpieces with incredible precision, reducing vibration during machining and ensuring parts remain stable even under intense forces.

Applications:

- Semiconductor Manufacturing: Ensures the highest level of accuracy for tiny components.

- Electronics Manufacturing: Ideal for high-volume, precision work in small spaces.

2. High-Precision Single Station Vises: Maximum Clamping Force for Repeatability

Kurt’s high-precision single station vises are designed for extreme accuracy. These vises provide up to 12,000 pounds of clamping force and are known for their ability to minimize jaw deflection by up to 80%. This enhanced stability is crucial in industries like aerospace and automotive, where even the smallest deviation in measurements can lead to costly errors.

Applications:

- Automotive Industry: Essential for prototype development and component manufacturing.

- Aerospace Sector: Ensures precision machining of components with tight tolerances.

3. Modular Vises: Versatility and Customization for Complex Projects

Modular vises offer unmatched flexibility, allowing machinists to configure custom setups tailored to their specific needs. With systems like SeraLock, WedgeLock, MoveLock, and MiniLock, these vises can be adjusted for various project types, from custom parts to prototypes. The modularity makes them perfect for shops that require quick setup changes without the need for replacing the entire vise system.

Applications:

- Custom Part Production: Ideal for businesses requiring adaptability in workholding setups.

- Prototype Development: Provides flexibility for creating unique designs without compromising precision.

4. Hydraulic Vises: Precision Clamping for High-Volume Production

Hydraulic vises offer consistent and repeatable clamping force, making them perfect for high-volume production environments. These vises maintain controlled clamping pressure, ensuring each workpiece is held with the same force every time. This is crucial for industries such as oil and energy, where consistency is key for large-scale manufacturing.

Applications:

- Oil and Gas Industry: Perfect for large-run production in harsh environments.

- High-Volume Manufacturing: Ensures uniformity and efficiency in repetitive tasks.

5. Specialty Vises: Tailored Solutions for Niche Applications

Kurt also offers specialty vises for unique applications, including self-centering vises, XL extra capacity vises, and the VB 5AX100 Schenke clamping system. These vises are built to accommodate specific requirements, such as securing large workpieces or providing precise positioning for complex geometries.

Applications:

- Medical Device Manufacturing: Useful for highly specialized and small-scale production runs.

- Defense Sector: Essential for holding uniquely shaped parts with extreme accuracy.

Why Choose Kurt Vises? Key Advantages

1. Unmatched Precision and Reliability

Kurt Vises are engineered for maximum precision, offering features like reduced jaw deflection and consistent clamping force. This ensures machinists can achieve repeatability and accuracy, even in high-stakes projects. Kurt’s commitment to quality is reflected in every vise produced, making them the go-to choice for precision-driven industries.

2. Iron-Clad Lifetime Warranty

Kurt Manufacturing backs its vises with an Iron-Clad Lifetime Warranty, offering peace of mind to customers. This warranty covers all defects in material or workmanship, emphasizing the company’s confidence in its products. With this assurance, businesses can depend on their Kurt Vises for many years without worrying about costly repairs or replacements.

3. Easy Access to Replacement Parts

Kurt Vises are built to last, and when components eventually wear out, replacement parts are readily available. Kurt Manufacturing provides a range of repair parts, including vise jaw kits, to ensure the longevity and performance of their products. Additionally, authorized repair centers across the United States offer expert maintenance services.

4. Sustainability Commitment

Kurt Manufacturing is dedicated to reducing its environmental impact. By using recycled materials in production and employing energy-efficient manufacturing processes, Kurt ensures that its products are not only high-performance but also environmentally responsible.

Key Industries Utilizing Kurt Vises

Kurt Vises are crucial tools in various high-precision industries, providing machinists with the reliability needed to handle critical operations.

Semiconductor Industry

The semiconductor industry demands extremely high precision, as even the smallest error can lead to catastrophic failures. Kurt Vises excel in this field by offering the necessary accuracy and stability to produce tiny, delicate components required for modern electronic devices.

Aerospace and Defense

The aerospace and defense industries require workholding solutions that can meet stringent quality standards. Kurt Vises provide the durability and repeatability needed to manufacture critical components, from engine parts to complex assemblies, ensuring the highest levels of safety and reliability.

Automotive Sector

The automotive industry relies on Kurt Vises for both prototyping and mass production. Whether it’s creating custom parts for electric vehicles or producing high volumes of components, these vises deliver the precision necessary to ensure quality and efficiency in manufacturing.

Oil and Energy

Kurt Hydraulic Vises are particularly well-suited for the oil and energy sectors, where heavy-duty clamping is often needed for drilling and other high-force applications. These vises provide the reliability and consistency necessary for repetitive tasks in demanding environments.

Factors to Consider When Choosing a Kurt Vise

When selecting a Kurt Vise for your operation, there are several key factors to consider:

- Size and Weight of Workpieces: Ensure that the vise can handle the size and weight of the parts you intend to secure.

- Clamping Force Requirements: Kurt offers vises with a wide range of clamping forces, from manual to hydraulic, so choose based on your needs.

- Jaw Width: The jaw width should match the scale of your projects to provide adequate stability.

- Type of Mounting: Kurt Vises can be mounted both horizontally and vertically, so choose the type that suits your machining setup.

- Frequency of Use: For high-volume production, consider hydraulic or modular vises for efficiency and consistency.

Maintenance Tips for Kurt Vises

To ensure your Kurt Vise continues to perform at its best, follow these maintenance tips:

Regular Cleaning

Debris buildup can cause misalignment or surface damage, so it’s essential to clean your vise regularly.

Lubrication

Keep moving parts lubricated to prevent wear and corrosion. Use suitable lubricants for each component.

Inspection

Regularly inspect the jaws, screws, and other parts for signs of wear. Replace any components that show damage.

Replacement of Worn Parts

To maintain performance, replace worn parts quickly. Kurt offers replacement kits and repair services to make this process straightforward.

Innovative Features of Kurt Vises

Kurt Manufacturing continues to innovate with cutting-edge technology in their vises. Some models come equipped with deflection reduction systems, ensuring maximum stability even under high clamping forces. Additionally, certain models feature computerized clamping pressure monitors, offering real-time feedback to operators for precise control over the clamping process.

Conclusion: Why Kurt Vises Are the Best Choice for Precision Workholding

Kurt Vises are the epitome of precision and durability, designed to meet the needs of industries where accuracy and consistency are paramount. With a wide range of options, including high-density, high-precision, modular, hydraulic, and specialty vises, Kurt ensures that there is a solution for every workholding requirement. Their commitment to quality, sustainability, and customer satisfaction makes Kurt Vises the go-to choice for professionals in aerospace, automotive, defense, oil, and semiconductor industries.

By investing in Kurt Vises, you’re not just purchasing a tool – you’re ensuring that your manufacturing processes are equipped with the best technology available, backed by a lifetime warranty and a company that stands behind its products. Whether you’re working on custom prototypes or large-scale production runs, Kurt Vises are designed to deliver the reliability and precision you need.